- HOME

- Serve Items

- Precision Manual Welding

Gas tungsten arc welding

- Gas tungsten arc welding (GTAW welding for short), or tungsten inert gas welding (TIG welding for short), is an arc welding method that uses non-melting tungsten electrodes for welding.

- Processing range:

Pipe fittings:Ø 1/4”-0.039”(6.35mm-wall thickness:1.0 t)~ Ø 450A(457.2mm-wall thickness:4.5 t)

Chamber/structure:sheet thickness3.2t - 50.0t - Welding standard:ASME SEC.XI 、AWS-D 1.6

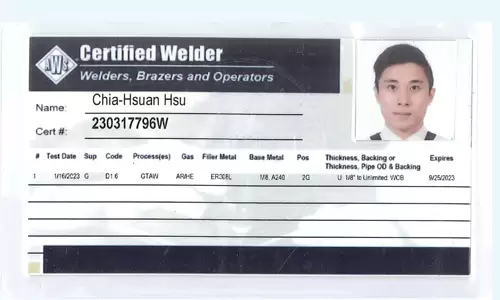

- Welding qualification:American Welding Society Certification Welder(AWS-CW)

- Inspection qualification:

American Welding Society Certified Welding Inspector(AWS-CWI)

ASNT ACCP Level II - Inspection specification:AWS-D17.1-RT、PT、LT、VT

- Material:stainless steel(SUS-304、SUS-316L)、Hastelloy(HASTELLOY)、nickel-based alloy(Nickel)、 Monel alloy

Technical certificate

Gas Metal Arc Welding

- Gas Metal Arc Welding (GMAW=Gas Metal Arc Welding), also commonly known as CO2 welding, is an arc welding process that generates metal coalescence by heating the metal with an arc between a continuously fed filler metal electrode and a workpiece. The process uses a shield of externally supplied gas to protect the molten weld pool.

- Processing range:

Pipe fittings:100A-0.11”(Ø 114.3 mm-wall thickness:3.0 t)~ Ø 450A-0.18”(457.2mm-wall thickness:4.5 t)

Chamber/Structure:sheet thickness 3.2t – 30.0t - Welding standard:DIN EN ISO 9606-1:2007 、ISO 9606-1 141P、 ISO 9606-1 136P

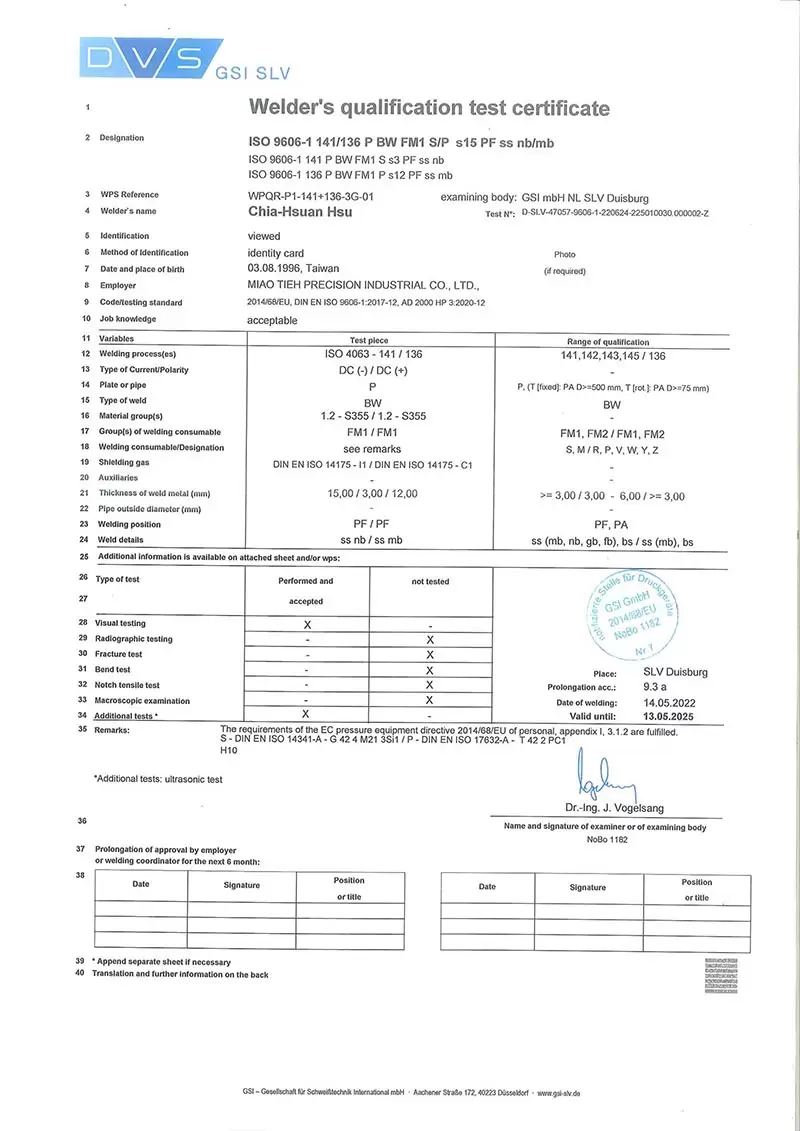

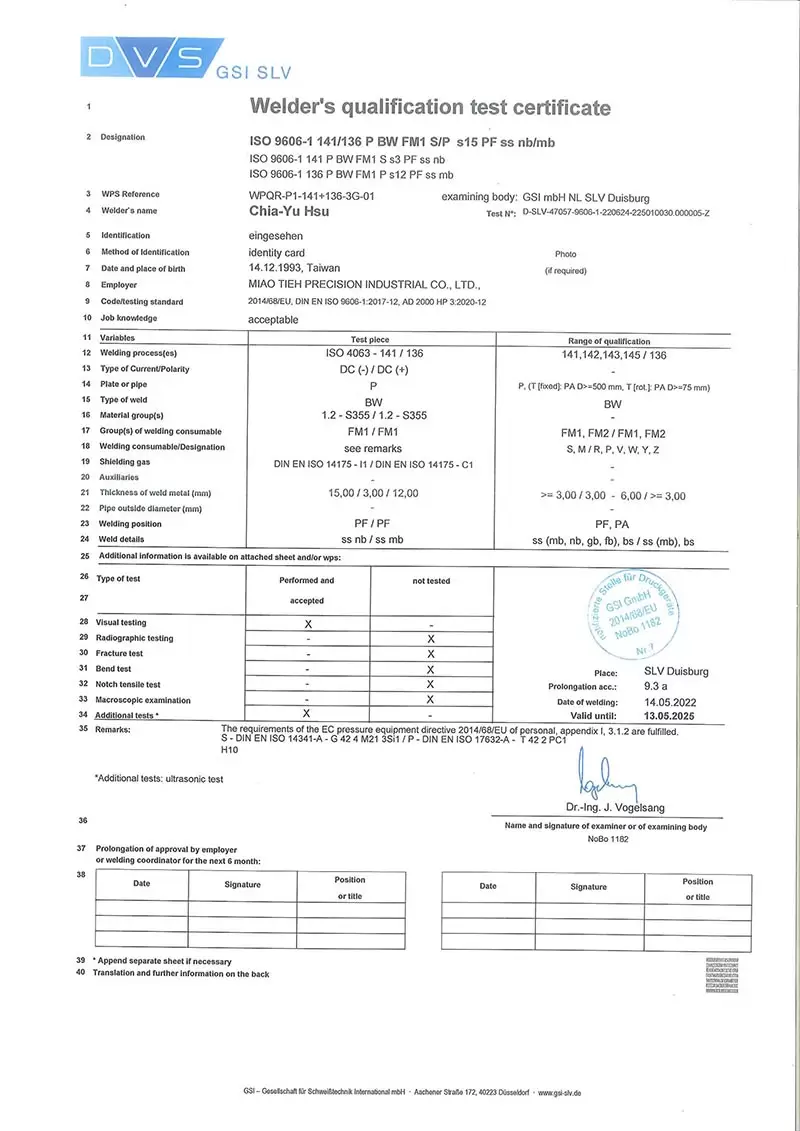

- Welding qualification:DVS GSI SLV Certificate Welder

- Inspection Qualification:

American Welding Society Certified Welding Inspector(AWS-CWI)

ASNT ACCP Level II - Inspection specification:ISO 5817、ISO 17637-UT、VT

- Material:stainless steel(SUS-304、SUS-316L)、carbon steel-S45C(A36)

Technical certificate