- HOME

- About Us

MIAO TIEH PRECISION INDUSTRIAL CO.,LTD.

Miao Tieh Precision Industrial Corp was formerly known as Miaoli Iron Factory and was established in August 1975. Initially, it undertook the manufacturing business of stainless steel related equipment such as large pressure tanks and vessels. With the rise of Taiwan's semiconductor industry and optoelectronics industry in the 1980s, Miao Tieh Precision Industrial Corp. The business transformed and expanded into the whole plant piping business of semiconductor and photovoltaic plants. It received excellent evaluation in the semiconductor industry, established good performance, and won the trust of customers for its quality.

In 2007, Miaoli Iron Factory was renamed Miaoli Precision Industry Co., Ltd., integrating the manufacturing technology of traditional industries with the rigorous precision of the semiconductor industry, transforming it into a professional semiconductor equipment integrated manufacturing plant, adhering to the business philosophy of integrity, using technology to improve and Product innovation serves as brand value, improves product and service quality, and takes customer satisfaction as the ultimate goal.

Product

semiconductor parts、Special Gas Line、Gas Panel、Piping More

Semiconductor

Vacuum

Food Grade

Aerospace Precision Welding

Customized Pressure Vessel

Certification

Quality policyOur quality management system complies with the international standard ISO 9001 certification,And it has undergone rigorous evaluation and certification.There is a strict quality management system when producing, manufacturing and delivering products.To ensure that our products meet the requirements of customers and international standards.

Part/Component Production Process

STEP01

Material Procurement

STEP02

Incoming Inspection

STEP03

Machining

STEP04

Ultrasonic Cleaning

STEP05

Precision Welding

STEP06

In-process Inspection

STEP07

Surface Treatment

STEP08

Ultrasonic Cleaning

STEP09

Dimensional Inspection

STEP10

Helium Leak Detection

STEP11

Saturation Test

STEP12

Final Cleaning

STEP13

Final Inspection

STEP14

Package

Equipment Production Process

STEP01

Material Procurement

STEP02

Incoming Inspection

STEP03

Machining

STEP04

Ultrasonic Cleaning

STEP05

Precision Welding

STEP06

In-process Inspection

STEP07

Surface Treatment

STEP08

Ultrasonic Cleaning

STEP09

Dimensional Inspection

STEP10

Clean Room Assembly

STEP11

Helium Leak Detection

STEP12

Saturation Test

STEP13

Final Cleaning

STEP14

Final Inspection

STEP15

Package

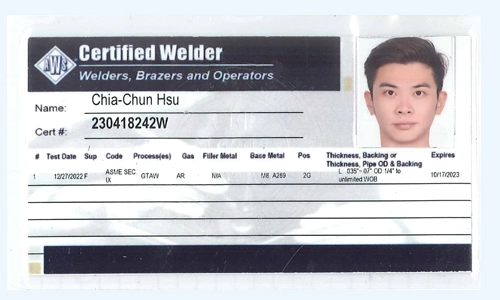

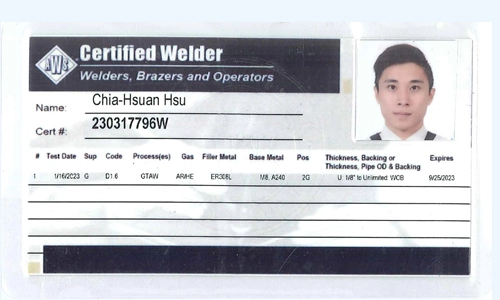

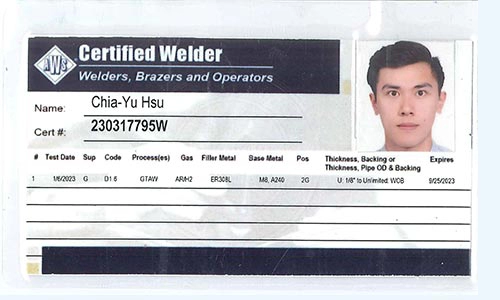

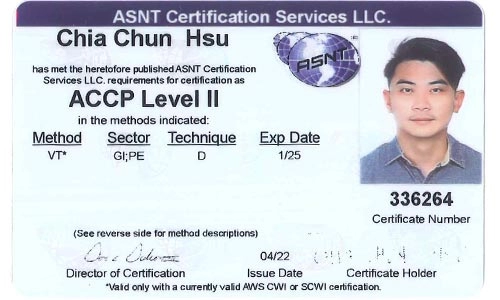

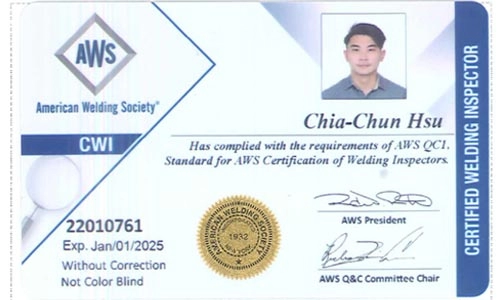

Employee Certificate

We attach great importance to the professional skills of our employees, so employees must obtain relevant professional certificates, to ensure that they have the corresponding professional knowledge and skills, to meet the qualified standards. You can trust our team with confidence, so we have all undergone rigorous assessment and training, and have the required professionalism and skills.

Argon Tungsten Electrode Welding T-HF-01

Argon Tungsten Electrode Welding T-HF-01

Argon Tungsten Electrode Welding T-HF-01

Argon Tungsten Electrode Welding T-HF-01

Argon Tungsten Electrode Welding T-HF-01